The FEV Group is an internationally recognized vehicle development services provider. FEV’s expertise ranges from consulting to the development and testing of innovative vehicle concepts through readiness for serial production. In addition to traditional engine and transmission development, vehicle integration, calibration, and the homologation of state-of-the-art gasoline and diesel engines, increasing importance is being placed on the development of hybrid and electric powertrains as well as alternative fuels. FEV experts now also focus on the advancement of electronic control systems, as well as connected vehicles and automation.

The FEV Software and Testing Solutions product portfolio complements these services with cutting-edge test fields, measuring equipment and software solutions that help make the development process more efficient and transfer significant process steps from the road to the test rig – or even to computer simulation.

The challenge is to develop more complex powertrains in less time. It causes a rapidly increasing demand to powerful but also intuitive solutions.

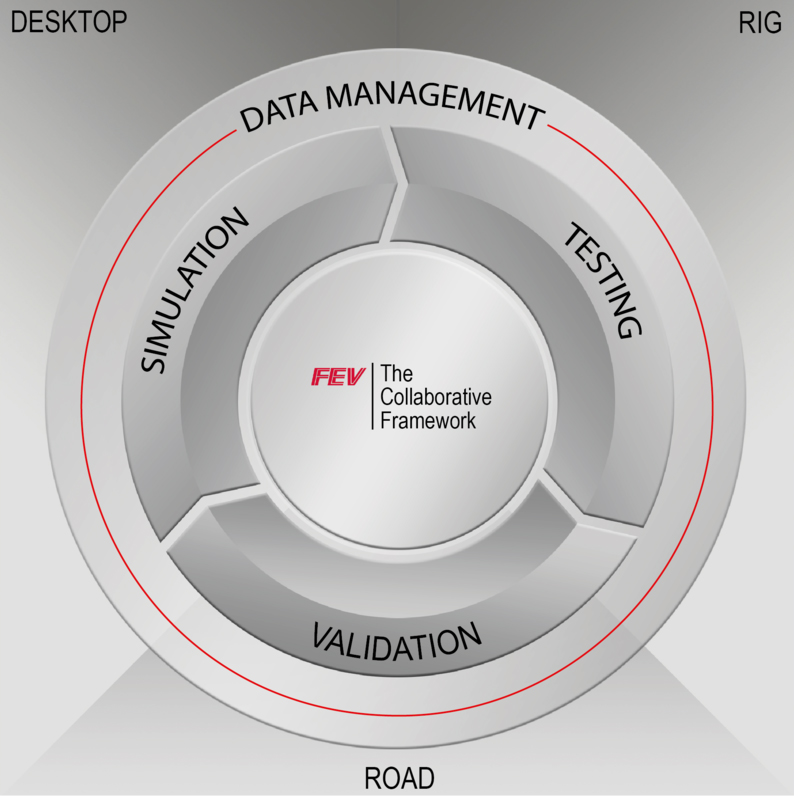

FEV’s decades of experience in powertrain dynamics simulation and multi-body system simulation have been incorporated into a unique collaborative framework meeting today’s engineering needs.

With the FEV Collaborative Framework, the powertrain models are initially implemented at the desktop, then send and executed at the test rig in real time, combined with physical components. In a final step, the real powertrain is validated on the road. From beginning to end, the engineers stay in the same software environment: FEVFLEX for information management and MORPHEE for processing the tasks.

Discover how FEVFLEX manages the data from the desktop to the test center, and then to the road. FEVFLEX is an information management software solution that offers much more than just the combination and administration of data. Our test field data management solution has been especially developed for high-level needs in dynamic systems and will help you to make the most effective decisions.

Experience our comprehensive and integrated range of tools for simulation, testing facilities and validation on the road: MORPHEE xMOD operating 3D models coming from Virtual Dynamics, MORPHEE Automation System, operating a highly dynamic electric test bed, xCAL for highly predictive DoE, and ASM box for OBD calibration.

Operate the FEV HiL test bed for calibration of your new ECU: vCAP, the virtual calibration platform using MORPHEE, is used to calibrate ECU functionalities by means of simulation in accordance with the new transient WLTC, WHTC and RDE operating cycles, thereby saving up to 30% of the physical tests.

Discuss with our experts how to increase the use of simulation in the development of your e-mobility solutions. Select MORPHEE xMOD, and make up your choice: use your own models, or benefit from the unique FEV experience in modelling complex systems for hybrid and electric vehicles. Then, discover our FEV e-motor and e-axle test bed solutions and ask for our other full range of e-mobility solutions, such as our battery and powertrain test beds.